PRODUZIONE IMPIANTI BIRRA

MADE IN ITALY

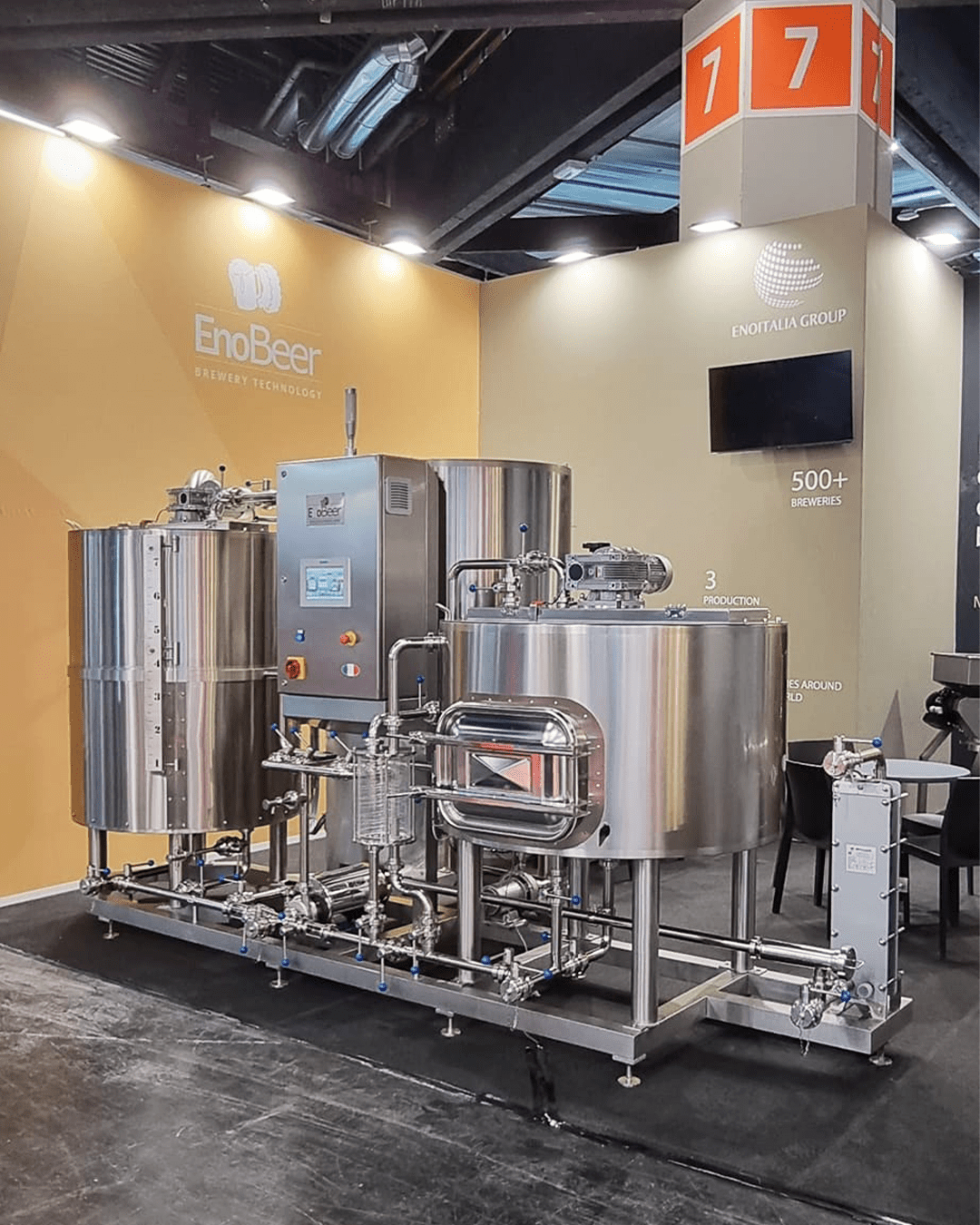

Specializzati nella realizzazione di Impianti Birra, miriamo a fornire una gamma di prodotti moderni, progettati sulle reali esigenze affidabili ed efficienti.

PRODUZIONE ITALIANA

Enoliexpo 2024 | 7-9 Marzo

Enoliexpo 2024 è alle porte! Vi aspettiamo numerosi in Fiera per vedere dal vivo i nostri impianti dal 7 al 9 Marzo!

Brau Beviale 2023

28° Edizione del SIMEI

Salone Internazionale Macchine per Enologia e Imbottigliamento

Beer Attraction & BBTech Expo 2018 – Rimini